Video extensometer

We use the non-contact video extensometer from the German manufacturer LIMESS to measure the elongation of material samples. This is integrated into our electronics via a serial interface. The non-contact measurement of elongation is not only important for steel or plastics, but also where contact with a specimen is not possible, such as films or paper. The measuring range is not dependent on the sample length and is up to 1000% elongation. Image fields of a few millimeters up to several meters are possible - thus also strain-controlled tests.

Sample breakage

Software breakage detection

RTSS Video extensometer

Technical description:

Camera RTSSCAM2.4MP

DCMU 2.4 MP, 2.4Megapixel (2000 x 1200 Pixel), 2/3“ Image sensor, USB3

- For high measuring accuracy in dynamic tests

- Accuracy class 1.0 with 100mm field of view

- 1µm resolution with 100mm image field width

- Longitudinal strain: resolution up to 0.002% strain

- Transverse strain over sample cross-section

- Measuring rate up to approx. 1500Hz

- Scope of delivery: Camera, USB3-cable 5m

Fixed focal length lens

Compact quality lens with fixed focal length.

Standard focal lengths: 12, 25, 35, 50, 75, 80 mm.

Optics are selected according to the application.

RTSS Measurement and control software

The RTSS (Real Time Strain Sensor) video extensometer is a non-contact strain measurement system based on a high-resolution digital camera and real-time image processing. It is mainly used automatically with tensile testing machines. Component deformation is measured with sub-pixel accuracy between two or more line markings. It is also possible to measure the movement of a marker during bending tests and for certification/calibration. The system is used for image fields of approx. 10mm to 2000mm.

Typical applications are the determination of material parameters [E-modulus, transverse contraction coefficient, etc.], strain-controlled tensile tests, crack tracking, cyclic tensile tests, dynamic and high-speed tests, vibration analysis, etc.

The data is transferred to external software and devices via a digital or analog interface. RTSS is 100% compatible with common tensile testing machines such as Instron, MTS, Zwick, Schenk, etc.

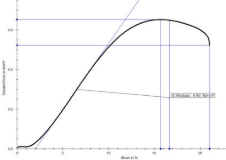

Determination of material parameters

Digital interface of the RTSS measurement and control software

Features:

- Video extensometer for use on (tensile) testing machines.

- Measuring rate typically 100 Hz (optionally up to 4KHz with special camera)

- Measurement of

- Longitudinal strain over 2 sample markings.

- Distance of the sample marker (calibration).

- Measurement of transverse strain via sample geometry.

- Constriction over sample cross-section.

- Width of the sample over the sample cross-section (calibration).

- Multiple marker detection: For a spatially resolved strain measurement, up to 20 line markers can be detected simultaneously.

- Measuring accuracy approx. 0.002% for longitudinal elongation (HR version)

- Saving images during the test. The images can be converted into an AVI using RTSS. The strain distribution can be measured using digital image correlation (optional at extra cost).

- Available interfaces: Serial, ASCII file, DOLI controller, DLL, Optional: Analog via DAQhw (2 channels, ±10V, 16bit).

- A modern, configurable and intuitive user interface

- Use of templates for various measurement tasks

- The thread-optimized kernel supports multi-core processors for a low processor load

- This allows, for example, installation on the control computer of the testing machine

- Scope of delivery: Software license, installation CD, online manual and short operating instructions.

Calibration plate

Calibration plate for calibrating the system (measured values in mm).

Field of view: 10 to 250mm (other sizes on request).

Marker set

Marker set for applying standardized line marks.

Scope of delivery: Marker template for L0=20 to 100mm, 1x black Edding, 1x white Edding, line sticker

High-power illumination (incident light)

Incident light (LED) for dynamic testing (not shown).