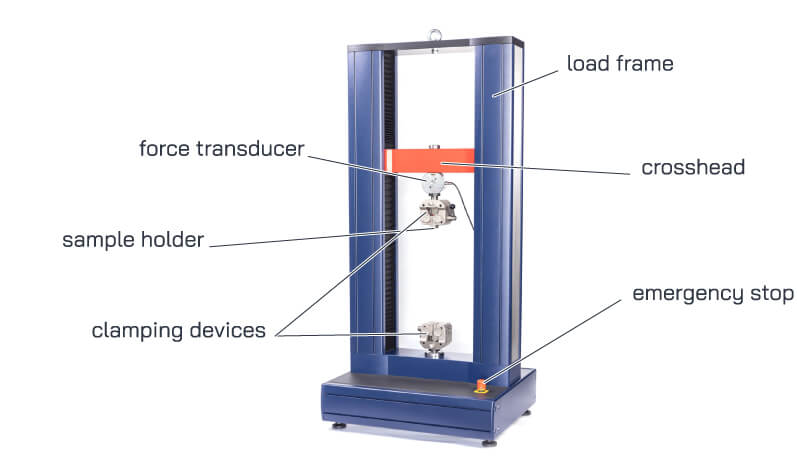

Testing machine

What can a tensile testing machine do?

We drive cars, walk over bridges and fly in airplanes. In everyday life, we encounter numerous products and objects made of materials such as metals and plastics. These have to withstand a variety of stresses and influences. Tensile testing machines are sometimes used to test their load limits and carry out quality assurance.

The term tensile testing machine is often used as a synonym for universal testing machine or, as described in the DIN EN ISO 7500-1 standard, materials testing machine.

The tensile testing machine is the universal testing device for determining the mechanical and technical properties of a material. It offers the possibility of testing materials in a wide variety of ways. These are destructive test methods.

General test types

In conjunction with clamping tools, a measurement and control electronics, and an evaluation software, a material testing machine can perform mechanical tests according to ASTM, ISO, and other industry standards for the determination of material characteristics. Possible types of tests would be:

- Tensile test

- Compression test

- Bending test (e.g. 3-point bending test)

- Shear tensile test

- Cycle test (e.g. fatigue test)

- Friction test

- Peel test

- Tear test

- Puncture test

Which material properties can be analyzed using tensile testing machines?

Material testing can produce detailed results about a material:

- Tensile strength / yield strength / deformation limit / damage limit

At what stress does the material begin to break/crack? - Compressive strength and breaking strength

At what pressure does the material start to break? - Holding force / adhesive force / frictional force

At what force do the materials no longer adhere to each other? - Transverse elongation / width reduction (R+N value for sheet metal)

At what tensile force does the material begin to deform transversely to the direction of load? - Peel strength

How high is the tensile force when the adhesive force of a material gives way?

Which materials can be tested?

The range of materials to be tested is enormous: it extends from material samples/test specimens (metal, rebar, wood, plastic, textiles, ceramics) to semi-finished products (screws, nuts, sheets, wire ropes) all the way to finished parts, assemblies, and structures.

Applications of the tensile testing machine

Thanks to their universal application, materials testing machines are at home in many industries. mpk-LUDWIG has more than one tensile testing machine in its range. We supply the smallest machine as a table-top unit with a force development of up to 100 kN.

The single-column testing machine X250-3 offers a force development of up to 3 kN. In addition to laboratory applications, this compact machine is also excellently suited for educational and school operations. With a power supply of 110 or 230 volts, it can be used internationally.

At the other end of our range is the mighty FS-600CT. This heavy-duty, top-class tensile testing machine is mostly used in the steel or concrete industry. It has a maximum tensile force of 600 kilonewtons. Even the strongest steels reach their limits.

Our range comprises a total of eleven universal testing machines, which can be equipped with a wide variety of superstructures for different test methods for every material.

Tensile testing machines from mpk-LUDWIG – Reliable materials testing machines to the highest standards

No matter which property you are testing, the quality of the materials testing machine is crucial for the validity of the measured values. For this reason, the quality of the machines we offer is our top priority. Our electromechanical tensile testing machines have many advantages.

- User-Friendly Testing Software ✔️ All machines feature a unique and user-friendly software that contains all material tests as a testing method. Furthermore, you can easily update the machine to the latest status thanks to free updates. Effortlessly create force-displacement diagrams, stress-strain diagrams, and much more. Programmable sequences simplify your internal processes

- Precision ✔️ Another feature of the machines is their above-average resolution and accuracy. This enables you to achieve the most precise measurement results and meaningful information on the quality and properties of the materials to be tested.

- Highest quality ✔️ Their elegant design and functionality meet the highest requirements. They exceed all national and international requirements for static tensile testing machines (ISO6892, ASTM E4, etc.)

- Reliable Results ✔️ Each material testing machine is equipped with a sensitive 24 mbit force sensor. This allows for a maximum resolution of the measured signals of less than one micrometer in the crosshead travel. Thus, the machines meet the DIN EN ISO 7500 standard in class 0.5. The high forces that act when generating tensile stress and when the material breaks are not a problem for the force sensors. They are standardly equipped with an 800% overload protection. This ensures the validity of the results remains absolutely reliable even with many tensile tests performed daily.

- Self-check at the touch of a button ✔️ With an automatic self-check, the user can check the functionality of the tensile testing machine at any time at the touch of a button. Precise long-term operation can thus be guaranteed.

- Low-maintenance System ✔️ Universal tensile testing machines from mpk-LUDWIG are designed for maximum wear resistance. The servomotor is brushless and thus maintenance-free. Using a digital incremental encoder, the theoretical resolution at the crosshead is 0.08µm. The ball screw spindles generate maximum force development with consistently precise control. Complete encapsulation, self-lubrication, and self-cleaning permanently minimize the maintenance and repair effort on the tensile testing machine. The result: You save on labor time and costs.

Tools for your test procedure

You can easily expand our universal material testing machines with up to six additional accessories. These include extensometers and micrometers, which can be expanded with up to four synchronized channels.

Additionally, you have the choice from a broad spectrum of various clamping tools for the standard-compliant testing of materials. Mechanically clamping tools, self-clamping wedge clamps, pneumatic clamping tools up to very large hydraulic clamping tools are available. Special tools for shearing, friction, or extraction tests are also available.

Would you like to carry out not only material samples, but also component tests? Just ask us! We have the solution!

A small excerpt from our selection of tools:

Calibration

Testing machines must also be subjected to continuous tests and calibrations in order to be able to guarantee the quality of measurement results on an ongoing basis. mpk-LUDWIG offers DAkkS calibration in its own laboratory or optionally on your premises.

Security

In most cases, the testing machines are used for destructive material testing. It goes without saying that the highest level of safety for users and the testing system is guaranteed. All safety requirements of the EC Machinery Directive are met and documented by an EC Declaration of Conformity.

Finding the right tensile testing machine

Professional advice is the be-all and end-all

Do you need to handle complex material analyses? mpk-LUDWIG, in detailed consultation with you, will find the optimal solution for you. Whether a standing machine or a bench-top device, our machines can be optimized for your requirements. For this, we carry a wide range of suitable components/testing tools, e.g., extensometers, clamping tools, thermal chambers, software, and further equipment for material testing.

Our mission: to help you obtain important information through reliable and fast test procedures. We can also assist you with our support beyond the purchase.

Inform now

Would you like to find out more about our range? We will be happy to advise you personally. Contact us at any time by phone or via our contact form.